Summary

READ ITIntroduction

Maintaining a well-managed inventory is crucial for the success of any e-commerce business. In this blog post, we will guide you through five steps to effectively align your inventory with fast-selling products while preventing stock-outs and boosting your sales.

Step 1: Define Fast-Selling Products

The first step in aligning your inventory is to identify the products that are in high demand. Sales data analysis is the key to choosing which products are selling fast. Dive into your sales data and look for products with consistent high sales volumes or those that experience sudden spikes in demand.

Also, our solution partner Fabrikatör offers default reports, where you can also find Fast-Selling-Products reports with a click. To save time and save yourself from creating the report all over again, we recommend you check Fabrikatör and its dynamic reports. Here's the screenshot of their Fast-Selling-Products report:

Step 2: Forecast Stockouts

To determine the average daily sales of your fast-selling products, you can obtain a report of the sales history for a given period of time and then divide the total number of products sold by the number of days in the period. This will give you an estimate of the daily sales for these products, allowing you to calculate the expected in-stock days.

You may also want to consider using Fabrikatör's forecasting, which automatically calculates the forecasted stock-out date for your products based on past sales data, giving you a more accurate estimate of when your stock will run out.

Step 3: Optimize Lead Times

After identifying your stock-out periods, it's crucial to consider your lead times to determine when to restock. Lead time refers to the duration between placing a purchase order and receiving the new inventory at your warehouse. When defining lead time, it is essential to consider both production time and transit time.

In addition, it is important to note that lead time can vary depending on the supplier and product. For example, if you have multiple suppliers, each supplier's lead time may be different. Moreover, if you're importing products from overseas, transit time can be significantly longer than if you're sourcing domestically. To optimize your inventory management, it's therefore recommended that you review your lead times periodically and adjust them as necessary.

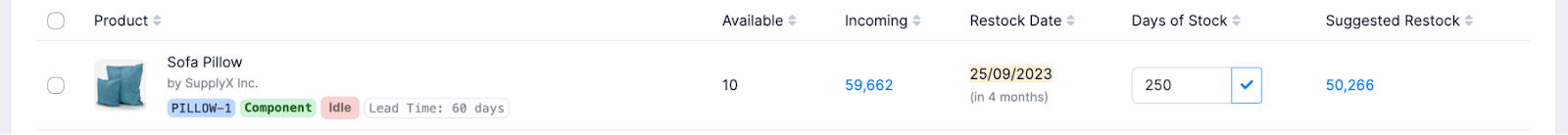

After determining when you'll run out of stock and how much time it takes to restock, you can create your Purchase Orders based on this calendar. With our partner Fabrikatör, after you set the lead times, it gives you the estimated restocking dates.

Step 4: Align Purchase Orders with Marketing Campaigns

When planning for campaigns or promotional activities for your fast-selling products, it is crucial to consider the estimated sales and factor them into your Purchase Order. With this step, you'll ensure your campaign can meet the expected sales without facing a stock-out. In other words, if you're planning or about to launch a campaign on your fast-selling product, also don't forget to and add the estimated sales to your PO.

Step 5: Regularly Monitor and Adapt for the Optimal Inventory

Monitoring the performance of your fast-selling products on an ongoing basis is vital to maintaining optimal inventory alignment. When you are enough stocked to meet the demand, you start catching more sales that you might have lost from an out-of-stock, and this directly leads to an increase in revenue.

Pro Tip: Unlock Revenue Potential with Backorders

Backorders enable your customers to buy your products when they are out of stock and capture the lost revenue of the sold-out products.

Studies show that 2/3 of consumers are willing to wait for their orders if the brand transparently communicates the expected timelines.

Here's our partner Fabrikatör's recommendation on how to make the best out of Backorder that boosts +10% revenue to stores they worked with:

1. Enable backorders for products that will be restocked in 14 days or less.

2. Use a waitlist for products that will be restocked in more than 14 days.

Also, always position the pre-order button as the primary option, superior to the waitlist. Additionally, it is important to inform your customers that products may sell out before the waitlist is processed, as products sell quickly on backorders.

Here's how your storefront will look when Fabrikatör backorder is activated for your product:

Conclusion

In conclusion, effectively aligning your inventory with fast-selling products increases revenue by being prepared for the forecasted demand. By following the five steps outlined in this blog post, you can prevent stockouts, increase sales, and provide a seamless shopping experience for your customers. Start with identifying your fast-selling products. Secondly, forecast stockouts by the sales history. Optimize your lead times to keep up with the customer demand and ensure timely replenishment of your inventory. Remember to add the sales expectations from a new campaign to your purchase orders. Finally, keep in mind that this is an ongoing process, so regularly monitor and adapt your fast-selling products, the changes in your lead times, and the sales demand.

With our solution partner Fabrikatör, you can dynamically see your fast-selling products with their related report. With Fabrikatör, you'll be able to know your stock-out days without any calculation, and after adding your lead times, it will give you restock suggestions for the products including the quantity and the time recommendation for the PO.

.webp)